We are AS 9100 Rev D and Nadcap Certified

About Us

Aerospace Company in Bangalore, India

Kun-Scalexuss is the most preferred and reliable business partner in the field of surface treatment, as we continue to align ourselves with our customer’s vision. Kun-Scalexuss operates to an extremely high standard and we have obtained the following approvals.

OEM and Prime Approvals

| SL | Process | AS 9100 REV D | NADCAP | PRATT & WHITNEY | COLLINS | ELBIT | EATON | PARKER | TRIUMP | HONEY WELL |

| 1 | CHEMICAL CONVERSION COATING | √ | √ | √ | √ | √ | √ | |||

| 2 | ANODIZING-SULFURIC | √ | √ | √ | √ | √ | √ | |||

| 3 | ANODIZING-HARD | √ | √ | √ | √ | √ | √ | |||

| 4 | SILVER PLATING | √ | √ | √ | √ | √ | ||||

| 5 | CADMIUM PLATING | √ | √ | √ | √ | √ | √ | |||

| 6 | ZINC PLATING | √ | √ | √ | ||||||

| 7 | ZINC NICKEL | √ | √ | √ | √ | |||||

| 8 | TIN PLATING | √ | ||||||||

| 9 | ELECTROLESS NICKEL | √ | √ | √ | √ | √ | √ | |||

| 10 | ENP-PTFE | √ | √ | √ | √ | √ | ||||

| 11 | PASSIVATION | √ | √ | √ | √ | √ | √ | √ | √ | |

| 12 | PAINTING (PRIMER, TOPCOAT & DFL) | √ | √ | √ | √ | √ | √ |

√ DFL |

||

| 13 | NDT-MPI & FPI | √ | √ |

How We Work

01. Lead-time optimisation

We provide finishing operations at our state-of-the-art facility, optimizing efficiency, reducing costs, and minimizing lead times. This technical expertise is vital as we partner with some of the world’s leading manufacturers.

02. Incoming parts inspection

Our dedicated staff thoroughly inspects all incoming deliveries to ensure that components arrive at Kun-Scalexuss in the same condition as when dispatched. Any discrepancies or issues identified are promptly communicated to the customer through our Quality Assurance department.

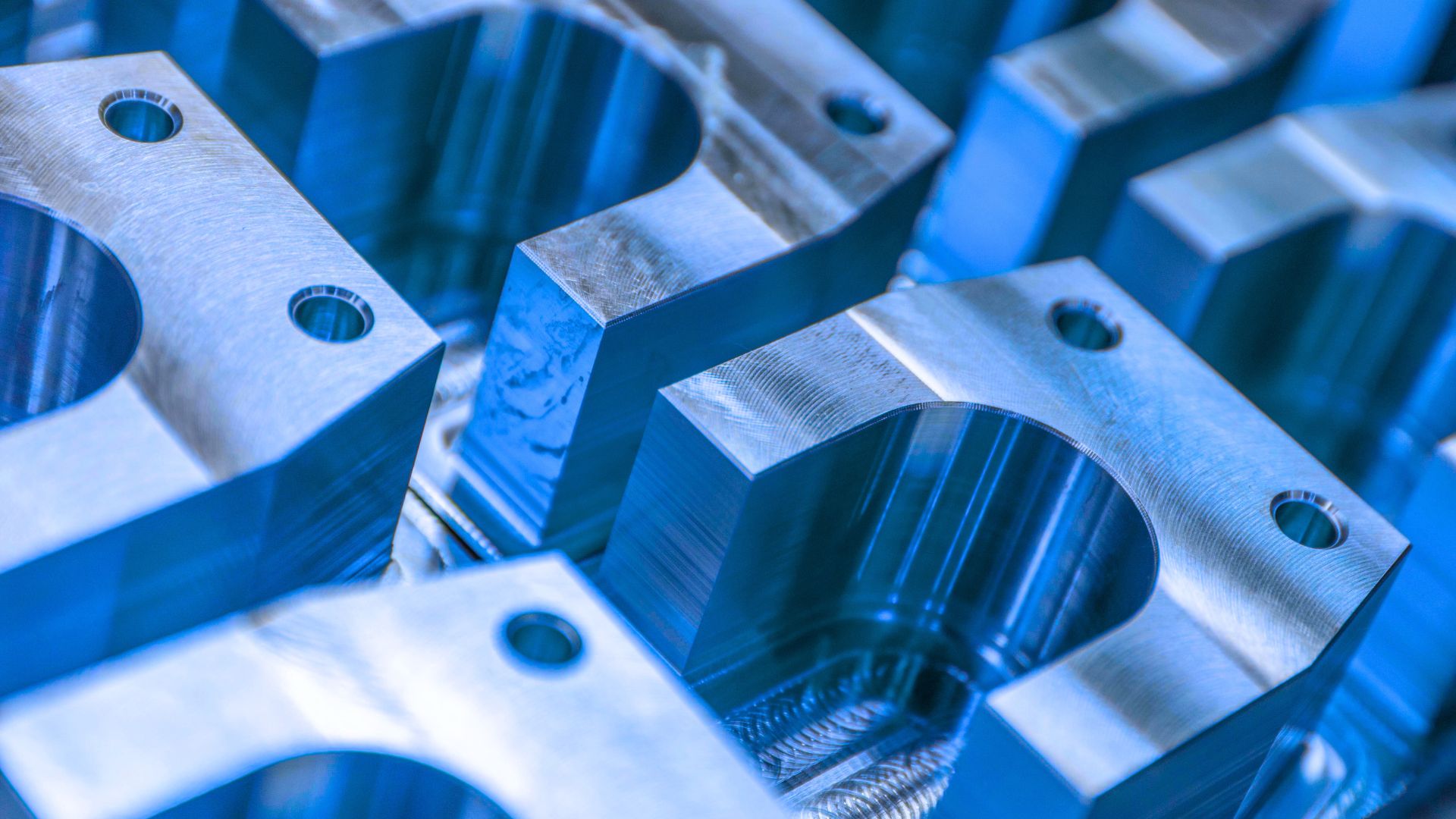

03. Streamlined Services Under One Roof

We offer a wide range of services, including Plating, Anodizing, Painting, Non-Destructive Testing, and Metallurgical and Chemical Laboratories, all under one roof. This integrated setup helps reduce lead times, transport costs, and delays. Parts can seamlessly transition between adjacent shops, streamlining processes and eliminating the need for costly transfers. Additionally, we coordinate with subcontractors to manage any external services required.

04. Dynamic and Flexible Meeting Space

Kun-Scalexuss’s open-plan office design fosters seamless communication and collaboration across key teams, including Production Control, Quality, Quotations, Planning, Health & Safety, Maintenance, and Finance.

Certified with AS9100 Rev. D and NADCAP servicing 1st Tier Engineering and Prime companies.

Our Key Services

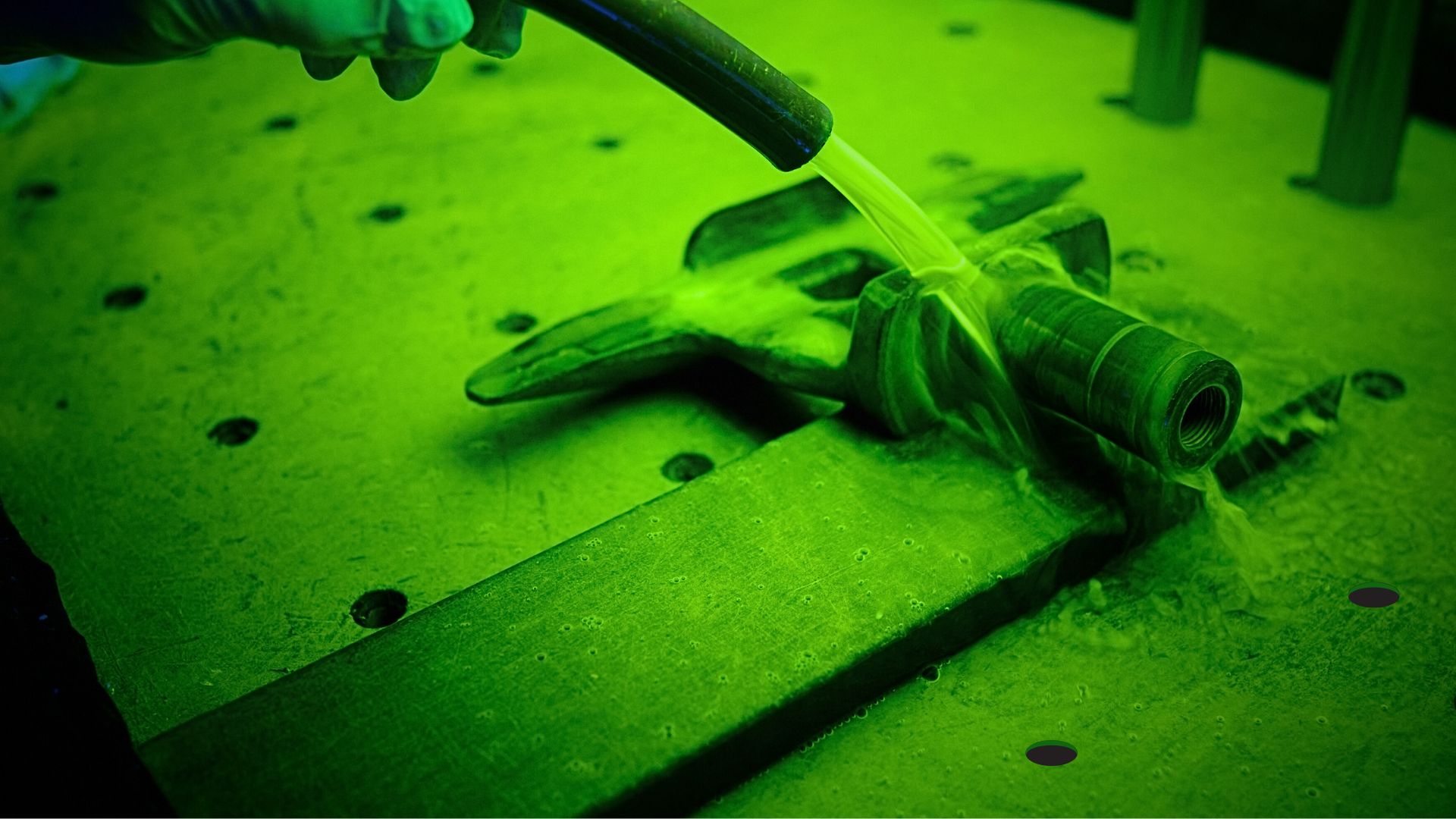

NDT and Etch Inspection

We make use of advanced technology and equipment to offer a non-destructive, accurate, and reliable method for assessing the quality of metals and alloys.

Conversion Coatings

Our state-of-the-art facility is designed to maximize batch quantities and production turnaround, ensuring the highest quality while maintaining competitive prices.

Anodizing

Kun-Scalexuss offers anodizing services, providing protective and decorative surface treatments for various industries, including aerospace, defence, and more.

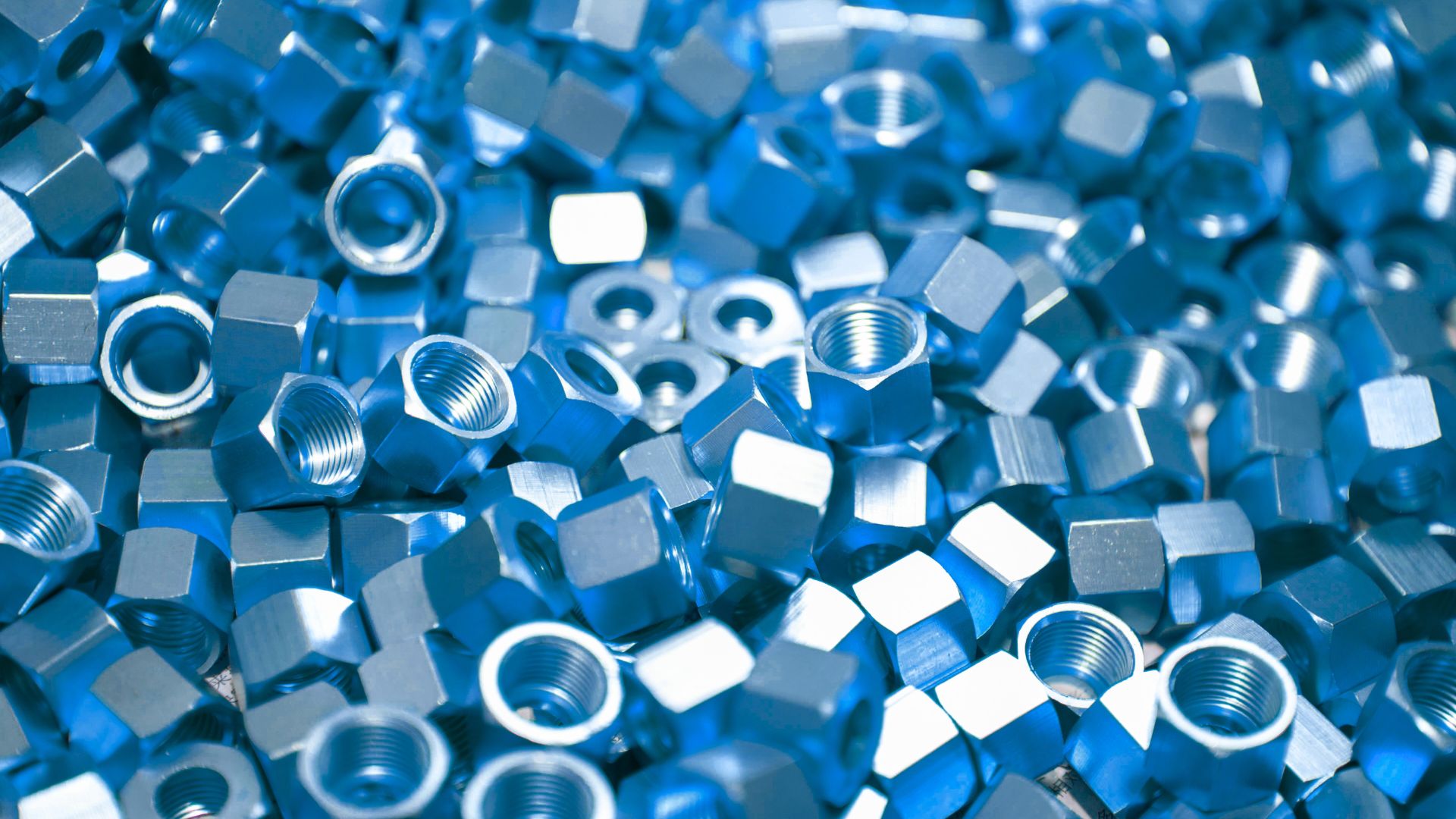

Plating

We provide metal finishes that protect against corrosion, enhance electrical conductivity, and improve the appearance of components for major aerospace and other industries worldwide.

Passivation

Kun Scalexuss offers passivation services, providing protective and decorative metal surface treatments for major aerospace and other industries worldwide.

Painting

Kun Scalexuss offers a range of processes under one roof, featuring a spacious paint shop equipped to handle multiple paint applications.

Abrasive Blasting

Helps prevent corrosion and extend the lifespan of metal components. This process also ensures optimal adhesion, enhances durability, and improves the appearance of the final coating.

Testing Capabilities

Kun Scalexuss offers a wide range of testing capabilities for a variety of industries, in compliance with customer-specific and international standards.

Serving Since Three Decades

Sectors We Serve

Aerospace

Electroplating of aerospace components such as landing gears, engine parts, and fasteners to improve their wear resistance, corrosion resistance, and electrical conductivity.

Defence

Surface Treatment of defence components such as firearms, armored vehicle parts, and military fasteners to enhance their wear resistance, corrosion resistance, and electrical conductivity.

Medical

Electroplating of medical components such as surgical instruments, implants, and dental devices to improve their biocompatibility, wear resistance, and corrosion resistance.

We take great pride in our work and are committed to ensuring that every project receives the highest level of care and attention to detail.

Get Quick Help

Mr. Ashok P

+91 99455 12749