High Quality Industrial Plating Solutions

Specialist In Electroplating

Kun-Scalexuss offers a range of plating services, providing metal finishes that protect against corrosion, enhance electrical conductivity, and improve the appearance of components for the aerospace industry and other sectors worldwide.

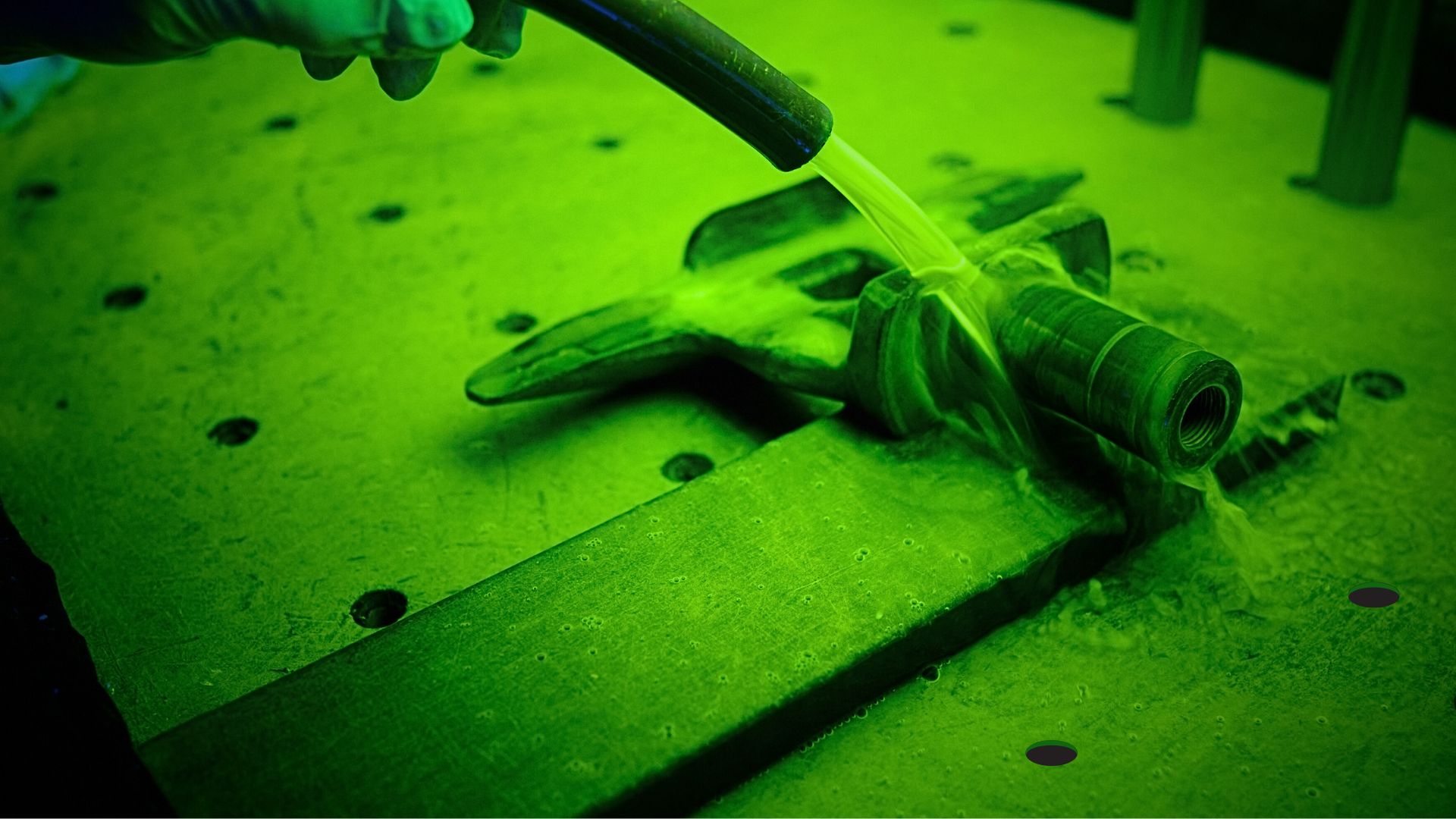

To ensure a high-quality finish, proper cleaning and surface preparation are essential for optimal bonding between the substrate and the plating layer. Our dedicated metal preparation area includes a variety of blasting and cleaning processes to guarantee that our customers receive a top-quality product.

Plating Services With Specification |

Tank Dimensions (mm) |

| ZINC PLATING ( AMS 2402, ASTM B 633 ) |

450 x 600 x 600 |

| ZINC NICKEL PLATING ( AMS 2417) |

450 x 600 x 600 |

| TIN PLATING ( ASTM B 545, AMS 2408 ) |

450 x 600 x 600 |

| SILVER PLATING (AMS 2410, AMS 2411, 914-026-037/041, ASTM B700 ) |

450 x 600 x 600 |

| CADMIUM PLATING ( AMS-QQ-P-416, AMS2400, AMS2401, PS100 ) |

450 x 600 x 600 |

| ELECTROLESS NICKEL PLATING ( AMS 2404, AMS-C-26074 ) |

450 x 600 x 600 |

| ELECTROLESS NICKEL/FLUOROCARBON (PTFE) ( AMS 2454, GPS 3117-1, 914-030-012-016 ) |

450 x 600 x 600 |

| COPPER PLATING ( AMS 2418, ASTM B 734 ) |

450 x 600 x 600 |

Different Types Of Plating Services

Cadmium Plating

Cadmium is a robust and versatile coating with a silvery-white metallic appearance and excellent corrosion resistance, functioning as a ‘sacrificial coating’ that corrodes before the substrate material. To further enhance its protective qualities, chromate conversion coatings can be applied over the cadmium plating.

Cadmium plating also provides an exceptional bonding surface for adhesives, making it a preferred choice in aircraft manufacturing and saltwater environments. Its electropositive nature to iron and low contact potential help minimise corrosion from dissimilar metals. However, cadmium is a controlled substance and can only be used in specific applications.

Silver Plating

Silver plating involves creating a circuit in an electrolytic solution that transfers microscopic silver particles to the substrate. While the process can be slow, it produces effective results. Silver is highly resistant to common chemicals and exhibits excellent heat resistance, remaining stable at high temperatures, making it ideal for power generation.

Its outstanding anti-galling and anti-fretting properties, due to lubricity and low friction, also make it suitable for automotive applications. Additionally, silver has the highest electrical conductivity of all metals, which is essential for both light and heavy current engineering. Its malleability, second only to gold, enhances its use in high-stress applications, such as slide bearings in aerospace.

Zinc Nickel Plating

Zinc-nickel plating is an electroplating technique that deposits a zinc-nickel alloy onto the target metal, with adjustable nickel content to achieve varying properties. For optimal results, we recommend an alloy with 15% nickel.

This method is favoured in the automotive and aerospace industries for its exceptional resistance to heat and corrosion. Tests on a 10-micron deposit demonstrate that it can withstand over 1000 hours of neutral salt spray. The alkaline solution ensures even alloy distribution.

Zinc-nickel plating is an environmentally safe alternative to cadmium, offering comparable or superior corrosion protection. It acts as a ‘sacrificial coating,’ corroding before the base material and minimising corrosion from dissimilar metals.

Zinc Plating

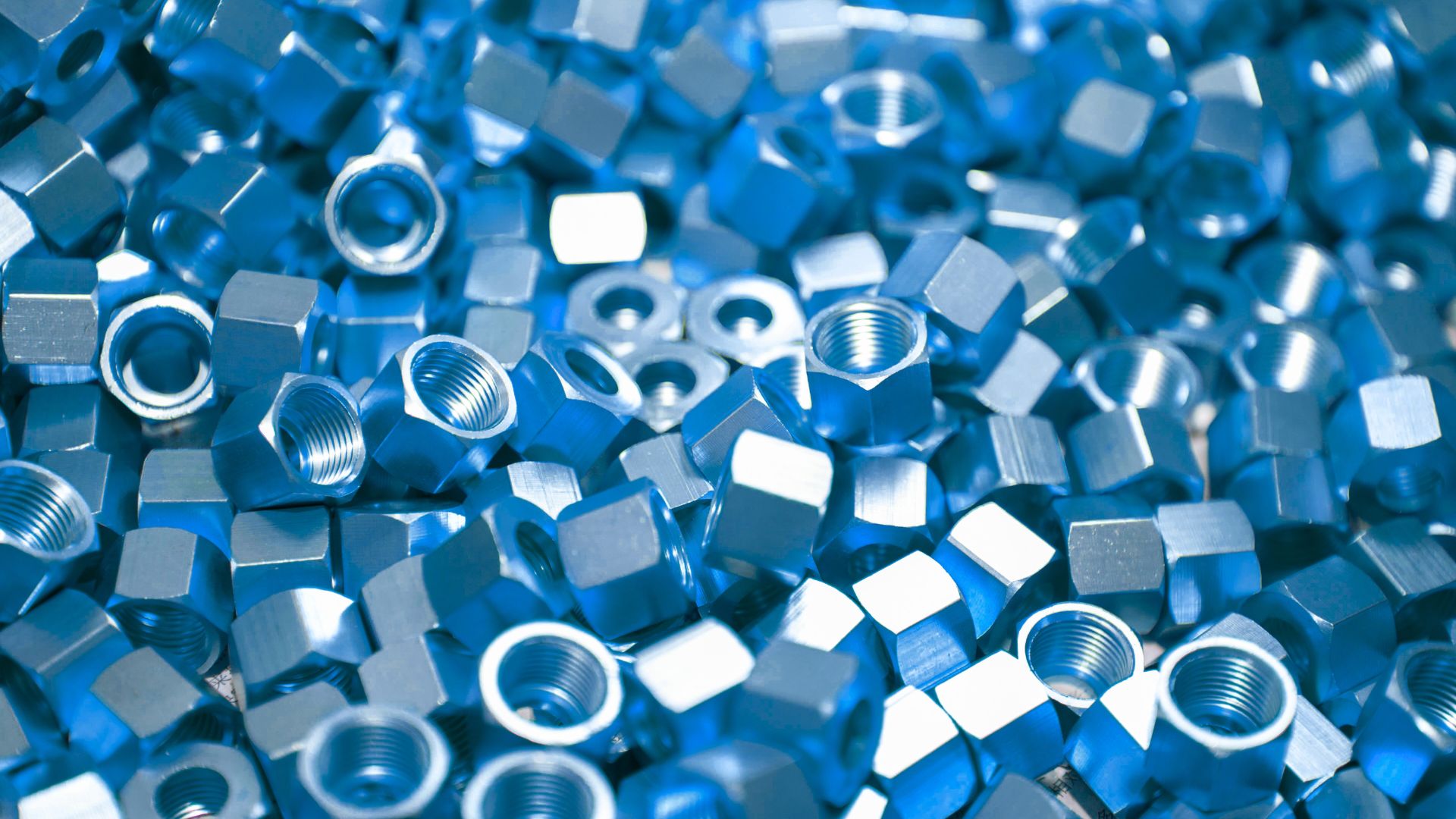

Zinc plating is commonly applied to ferrous metals like iron and steel, making it versatile for both small and large batches. It is often used for components such as fasteners, pressings, and springs, serving a wide range of industries.

With excellent corrosion resistance, zinc plating is ideal for sectors requiring long-lasting, rust-free components, particularly in offshore engineering. As a sacrificial coating, zinc corrodes before the base metal, providing time to address any rust issues.

Zinc-plated metal features a bright finish, with options for clear, yellow, or black passivation. Additionally, the process offers environmental benefits, enhancing its appeal across multiple sectors.

Copper Plating

Copper plating is widely used in the electronics industry, serving as a reliable masking for nitride hardening. Known for its distinctive shiny orange colour, copper is a soft and ductile metal with excellent electrical conductivity—ten times that of carbon steel. This makes it ideal for decorative purposes and a variety of applications.

The electroplating process produces a smooth, even surface, providing an excellent base for primers, paints, and adhesives. While copper is not as corrosion-resistant as harder metals, it performs adequately and can be paired with nickel plating for enhanced protection. Additionally, copper is abundant and cost-effective compared to noble metals like gold or silver.

Tin Plating

Tin plating, or electro-tinning, enhances functionality, aesthetics, and longevity. Tin is a silver-white metal with good corrosion resistance and excellent solderability due to its low melting point, making it suitable for various industries, including aerospace and automotive. Its conductivity also makes it valuable in the electrical sector, while its non-toxic properties are ideal for food processing applications.

Tin can be plated onto materials such as steel, stainless steel, copper, and copper alloys, with standard thicknesses ranging from 5 to 30 µm, though higher thicknesses are available. It can be applied in either a bright or dull finish, offering excellent corrosion resistance and solderability.

Electroless Nickel Plating

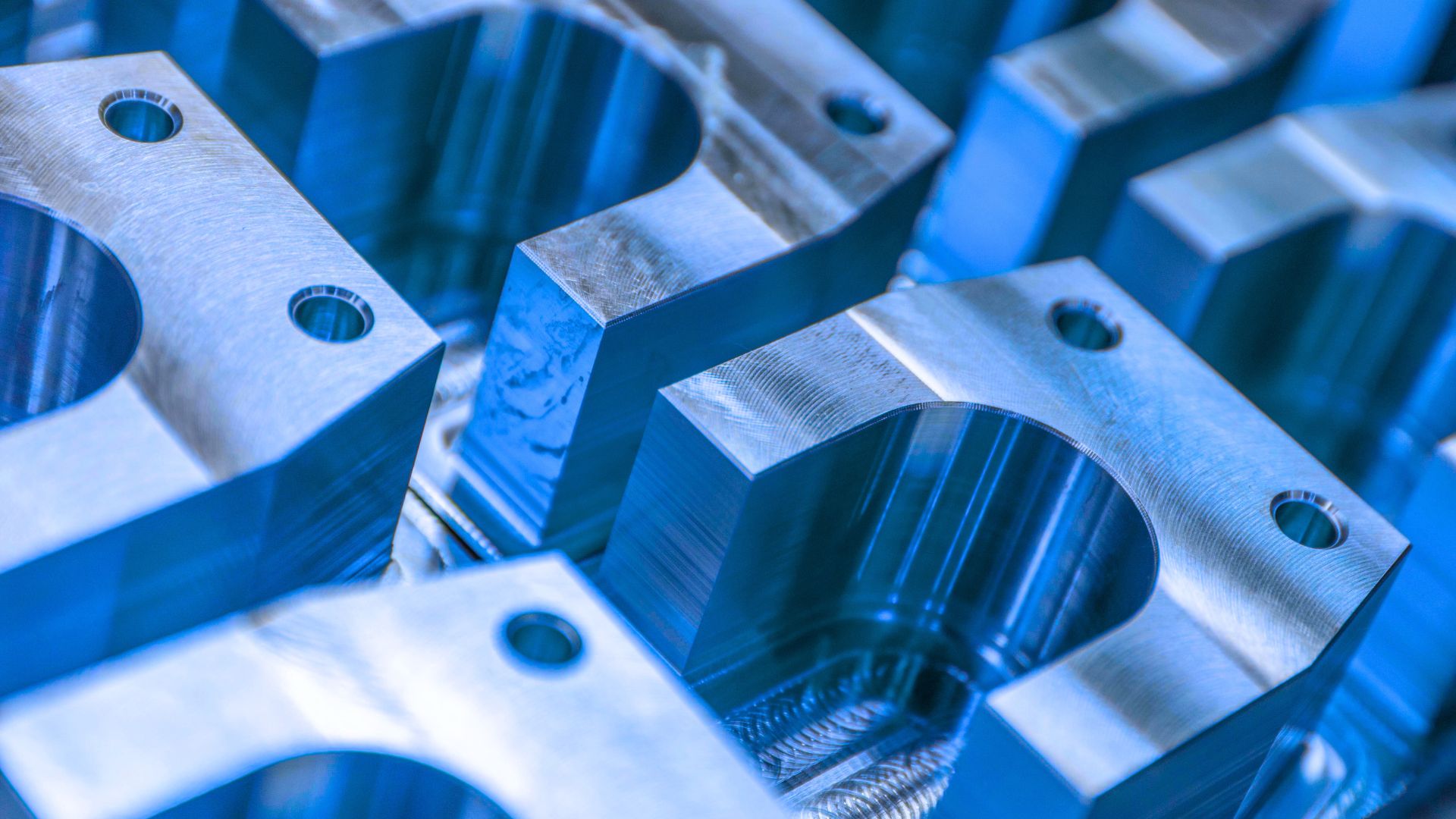

Electroless nickel plating offers numerous advantages, primarily its energy efficiency, as it does not rely on electrical current to deposit nickel onto surfaces. Using an immersion method, it effectively coats complex shapes, ensuring comprehensive coverage that other methods may not provide. The resulting nickel layer is uniform, eliminating concerns about surface irregularities, which is particularly beneficial for repairing worn components.

Additionally, this plating technique produces a finished surface with exceptional corrosion resistance, significantly enhancing the longevity of the treated material in a variety of environments. Kun-Scalexuss stands out by leveraging these benefits in its plating services.

Electroless Nickel PTFE

Electroless nickel PTFE is an advanced coating with self-lubricating properties, providing a hard, uniform layer that is precisely applied. Customising the chemical composition of the electroless nickel PTFE coating is crucial for optimising performance based on specific application needs. Our application engineers specialise in formulating the ideal solution for your requirements.

This composite coating effectively combines the low-friction benefits of PTFE with the durable, wear-resistant qualities of electroless nickel. Its self-lubricating nature makes it an excellent choice for components and assemblies that cannot accommodate conventional lubricants. The PTFE particles are finely reduced to sub-micron spheres, ensuring optimal content and uniform distribution.

Certified with AS9100 Rev. D and NADCAP servicing 1st Tier Engineering and Prime companies.

Our Key Services

NDT and Etch Inspection

We make use of advanced technology and equipment to offer a non-destructive, accurate, and reliable method for assessing the quality of metals and alloys.

Conversion Coatings

Our state-of-the-art facility is designed to maximize batch quantities and production turnaround, ensuring the highest quality while maintaining competitive prices.

Anodizing

Kun-Scalexuss offers anodizing services, providing protective and decorative surface treatments for various industries, including aerospace, defence, and more.

Plating

We provide metal finishes that protect against corrosion, enhance electrical conductivity, and improve the appearance of components for major aerospace and other industries worldwide.

Passivation

Kun Scalexuss offers passivation services, providing protective and decorative metal surface treatments for major aerospace and other industries worldwide.

Painting

Kun Scalexuss offers a range of processes under one roof, featuring a spacious paint shop equipped to handle multiple paint applications.

Abrasive Blasting

Helps prevent corrosion and extend the lifespan of metal components. This process also ensures optimal adhesion, enhances durability, and improves the appearance of the final coating.

Testing Capabilities

Kun Scalexuss offers a wide range of testing capabilities for a variety of industries, in compliance with customer-specific and international standards.

Serving Since Three Decades

Sectors We Serve

Aerospace

Electroplating of aerospace components such as landing gears, engine parts, and fasteners to improve their wear resistance, corrosion resistance, and electrical conductivity.

Defence

Surface Treatment of defence components such as firearms, armored vehicle parts, and military fasteners to enhance their wear resistance, corrosion resistance, and electrical conductivity.

Medical

Electroplating of medical components such as surgical instruments, implants, and dental devices to improve their biocompatibility, wear resistance, and corrosion resistance.

We take great pride in our work and are committed to ensuring that every project receives the highest level of care and attention to detail.

Get Quick Help

Mr. Ashok P

+91 99455 12749