Abrasive Blasting

Specialist In Abrasive Blasting

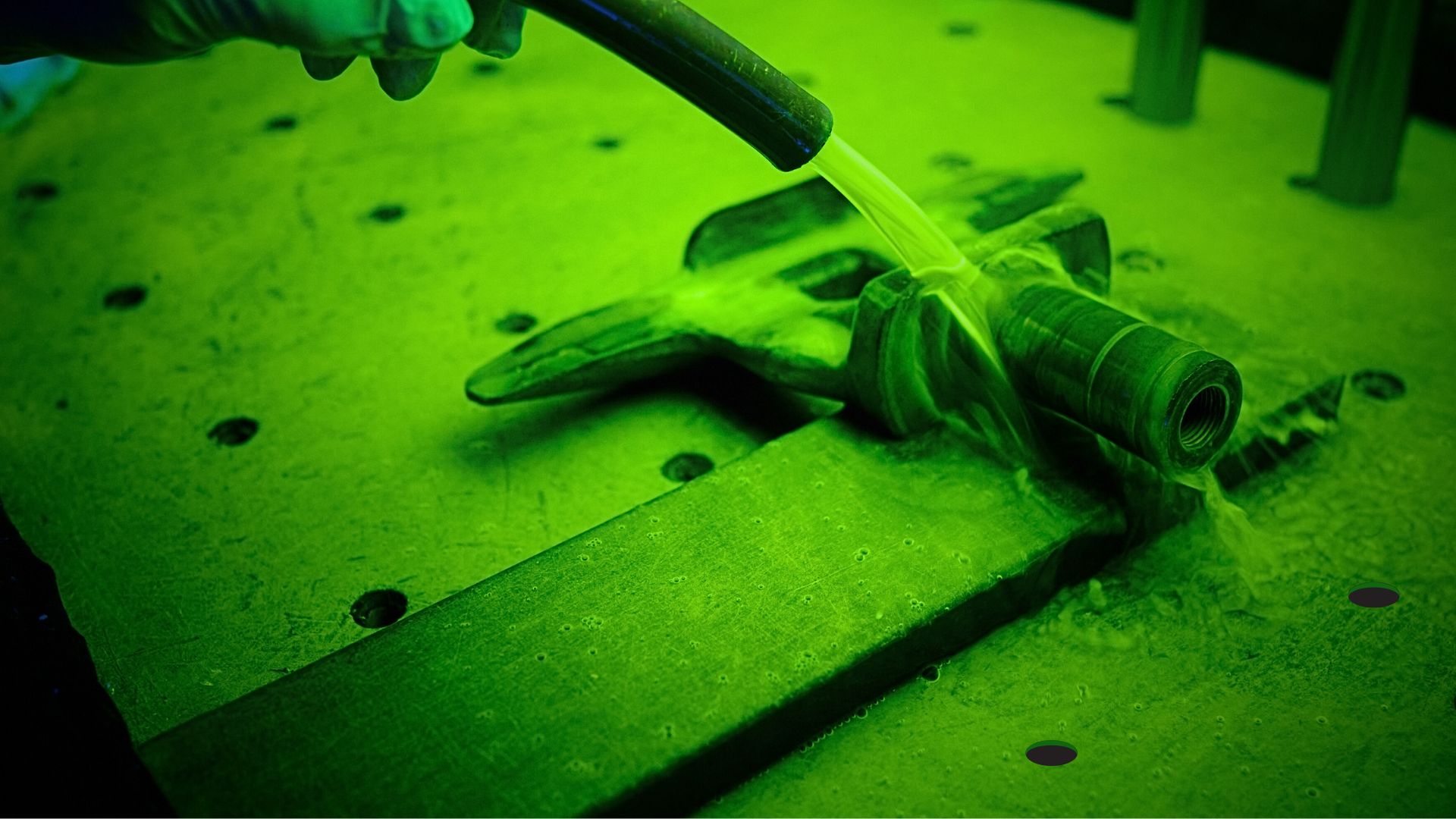

Abrasive blasting is a surface preparation technique used to clean, finish, or shape materials by propelling abrasive particles at high speeds. This method is crucial in various industries for preventing corrosion, as it removes rust, old coatings, and surface contaminants, thereby extending the lifespan of metal components. Additionally, abrasive blasting enhances surface profiles, improving adhesion for subsequent coatings and ensuring a more durable finish. It also improves the aesthetic appeal of surfaces by providing a uniform finish and eliminating blemishes.

Versatile enough for a wide range of materials, including metals, plastics, and glass, abrasive blasting can be tailored to meet specific project requirements. Many modern materials are designed to be environmentally friendly, minimising health and safety risks.

Abrasive Blasting |

Tank Dimensions (mm) |

| Alumina Grit | 500 X 400 X 400 |

| Glass Bead | 500 X 400 X 400 |

Kun-Scalexuss offers abrasive blasting services designed to prevent corrosion and extend the lifespan of metal components.

This process also ensures optimal adhesion, enhances durability, and improves the appearance of the final coating.

Types Of Abrasive Blasting Services

Alumina Grit

Grit blasting prepares surfaces by removing mill scale, rust, heat scale, and contaminants. This results in a clean surface that allows for accurate evaluations. Additionally, coatings and linings applied to properly prepared surfaces offer enhanced protection against corrosion and erosion, improving both the performance and lifespan of the coating and the underlying equipment.

Grit blasting effectively removes old coatings and contaminants while creating an anchor profile for improved adhesion of subsequent layers, ultimately increasing the efficiency and longevity of various plant and equipment.

Glass Bead

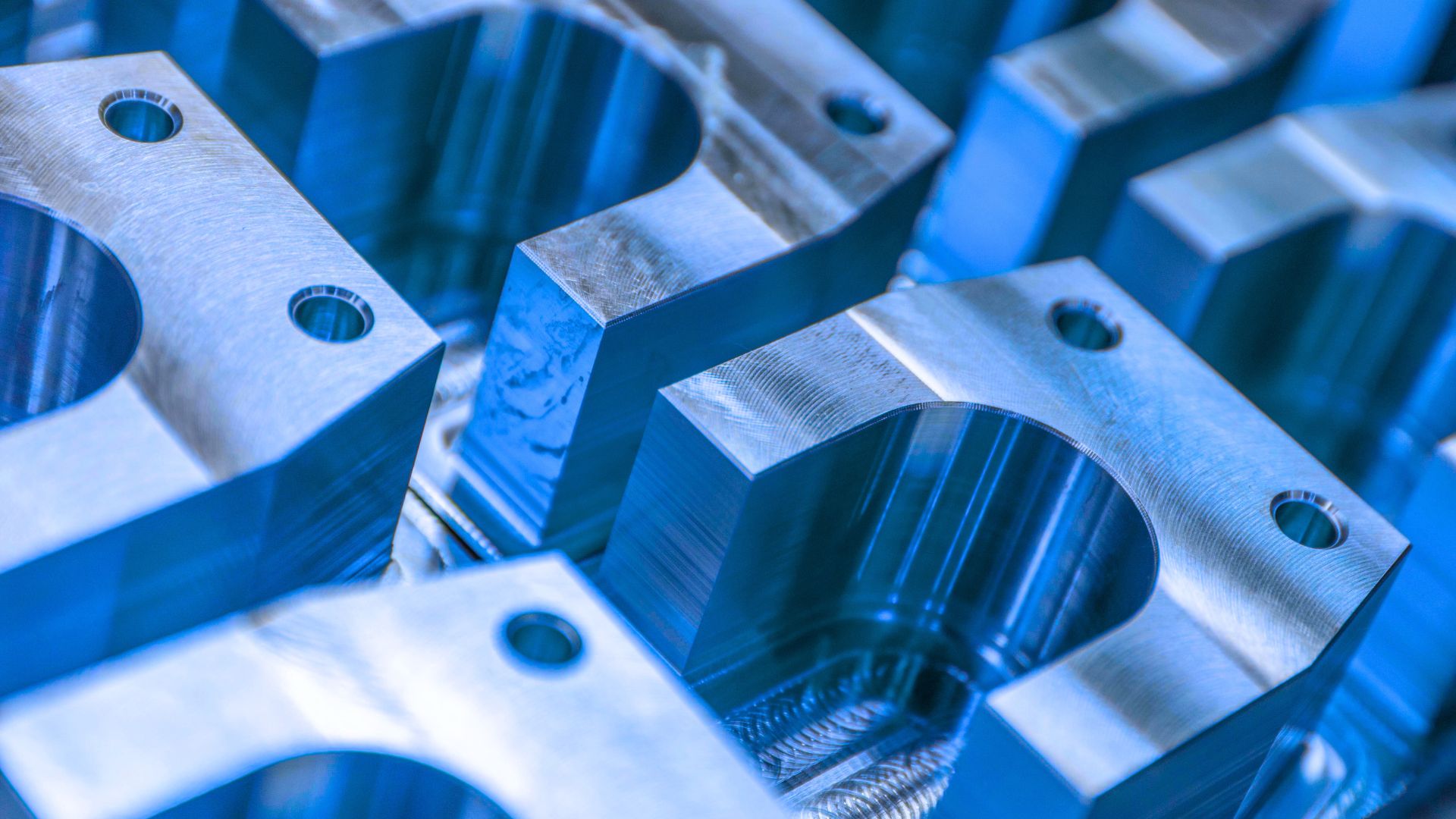

Glass bead blasting is a precise process that involves propelling small glass beads against aluminium parts within a specialised blasting cabinet. Using a high-pressure blasting gun, this technique creates a polished, uniform surface.

After glass bead blasting, the aluminium part appears lighter in colour, with a brighter overall finish. This method effectively provides gentle cleaning, surface smoothing, light deburring, and helps preserve the integrity and aesthetics of the aluminium, resulting in a consistent, polished appearance.

Certified with AS9100 Rev. D and NADCAP servicing 1st Tier Engineering and Prime companies.

Our Key Services

NDT and Etch Inspection

We make use of advanced technology and equipment to offer a non-destructive, accurate, and reliable method for assessing the quality of metals and alloys.

Conversion Coatings

Our state-of-the-art facility is designed to maximize batch quantities and production turnaround, ensuring the highest quality while maintaining competitive prices.

Anodizing

Kun-Scalexuss offers anodizing services, providing protective and decorative surface treatments for various industries, including aerospace, defence, and more.

Plating

We provide metal finishes that protect against corrosion, enhance electrical conductivity, and improve the appearance of components for major aerospace and other industries worldwide.

Passivation

Kun Scalexuss offers passivation services, providing protective and decorative metal surface treatments for major aerospace and other industries worldwide.

Painting

Kun Scalexuss offers a range of processes under one roof, featuring a spacious paint shop equipped to handle multiple paint applications.

Abrasive Blasting

Helps prevent corrosion and extend the lifespan of metal components. This process also ensures optimal adhesion, enhances durability, and improves the appearance of the final coating.

Testing Capabilities

Kun Scalexuss offers a wide range of testing capabilities for a variety of industries, in compliance with customer-specific and international standards.

Serving Since Three Decades

Sectors We Serve

Aerospace

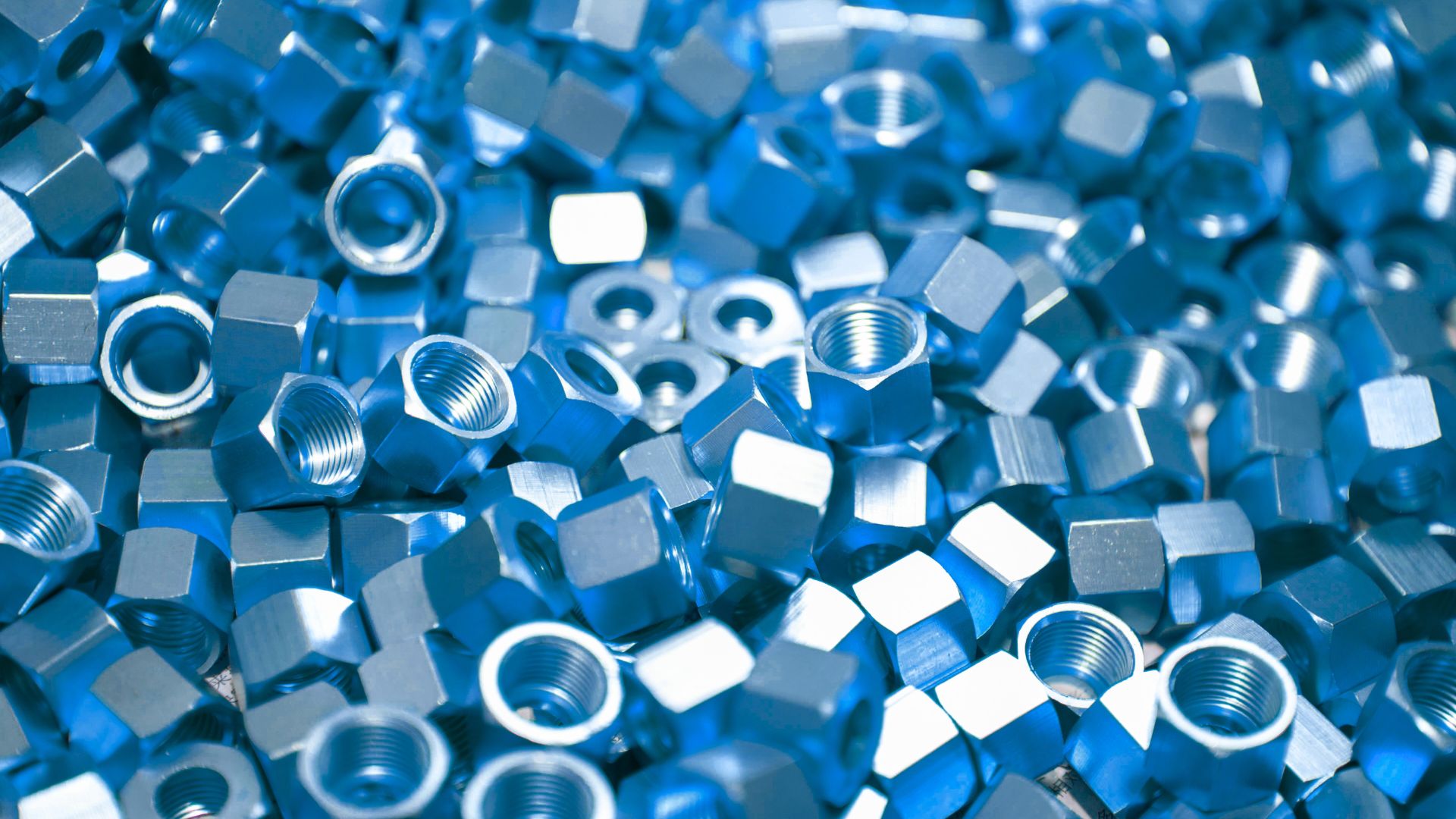

Electroplating of aerospace components such as landing gears, engine parts, and fasteners to improve their wear resistance, corrosion resistance, and electrical conductivity.

Defence

Surface Treatment of defence components such as firearms, armored vehicle parts, and military fasteners to enhance their wear resistance, corrosion resistance, and electrical conductivity.

Medical

Electroplating of medical components such as surgical instruments, implants, and dental devices to improve their biocompatibility, wear resistance, and corrosion resistance.

We take great pride in our work and are committed to ensuring that every project receives the highest level of care and attention to detail.

Get Quick Help

Mr. Ashok P

+91 99455 12749