Anodizing: Expert Services for Metal Surface Treatment.

Specialist In Anodizing

At Kun-Scalexuss, we offer a range of anodizing options tailored to meet specific manufacturing needs. Our anodizing process enhances corrosion and wear resistance, while also improving adhesion for paints and adhesives.

Our anodizing process is applicable to a diverse range of products, including aircraft landing gear, climbing gear, architectural panels, and decorative picture frames. This treatment not only fortifies the metal against wear and damage but also ensures greater resistance to rust and environmental degradation.

Additionally, the anodized surface is porous, allowing for the incorporation of vibrant dyes, which adhere securely without the risks of peeling or flaking typically associated with conventional paints.

Aluminium Alloy Anodizing Processes and Specs |

Tank Dimensions (mm) |

| Chromic Anodise ( MIL-PRF-8625 ) | 550 X 1200 X 800 |

| Sulphuric Anodise ( MIL-PRF-8625, ACES 1758 P1, PS102 ) | 550 X 1200 X 800 |

| Hard Anodising ( MIL-PRF-8625, PS104 ) | 550 X 1200 X 800 |

| Tartaric Sulphuric Anodise | 550 X 1200 X 800 |

Kun-Scalexuss offers Anodizing Services, providing protective and decorative surface treatments for various aerospace, defence and other industries.

Different Types Of Anodizing Services

Sulphuric Acid Anodizing

Sulphuric anodizing is exceptionally durable and provides excellent corrosion resistance. This process forms an oxide layer both internally and externally on the metal, resulting in a clear finish that readily absorbs coloured dyes. Sulphuric acid anodizing is suitable for a wide range of general engineering and decorative applications, as well as for use in the defence and aerospace sectors.

Hard Anodizing

Hard anodizing is an advanced form of sulphuric anodizing that produces a thicker, denser, and more durable finish. A hard anodized metal part typically features a much darker decorative finish, making it unsuitable for colouring. The wear resistance of hard anodized metals, such as aluminium, can rival that of steel, offering a lightweight and cost-effective solution.

Chromic Acid Anodizing

Chromic anodizing produces a thin oxide film that offers good corrosion resistance, but due to its limited thickness, it is not suitable for dyeing. As the chromic anodized film is so thin, it does not affect the precision tolerances required in the aerospace and defence industries.

Tartaric Sulphuric Acid Anodising

Tartaric Sulphuric Anodizing (TSA) is used in aerospace and defence applications, offering high corrosion resistance and excellent paint bonding. It is also more environmentally friendly, making it a strong alternative to chromic anodizing.

Certified with AS9100 Rev. D and NADCAP servicing 1st Tier Engineering and Prime companies.

Our Key Services

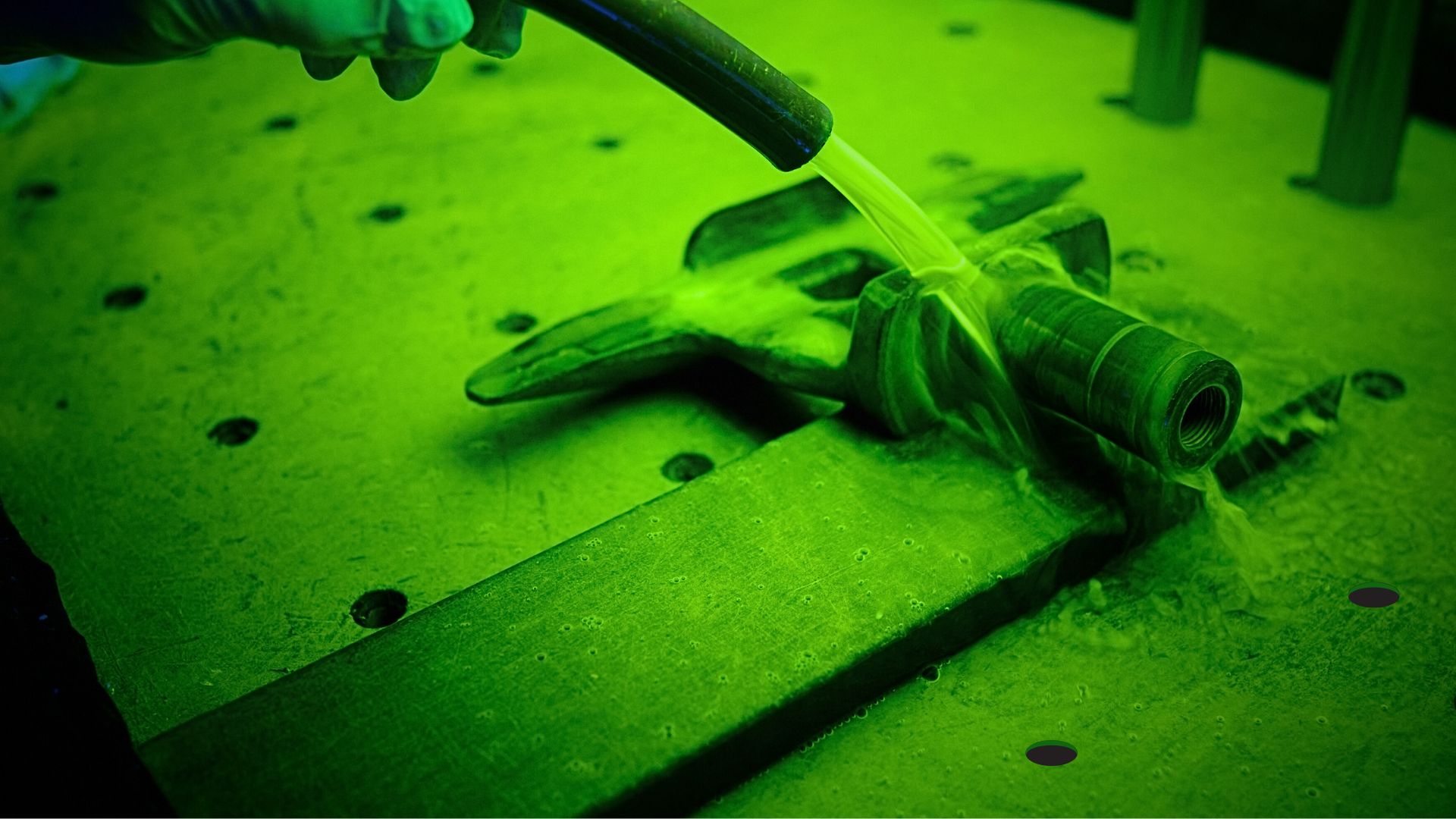

NDT and Etch Inspection

We make use of advanced technology and equipment to offer a non-destructive, accurate, and reliable method for assessing the quality of metals and alloys.

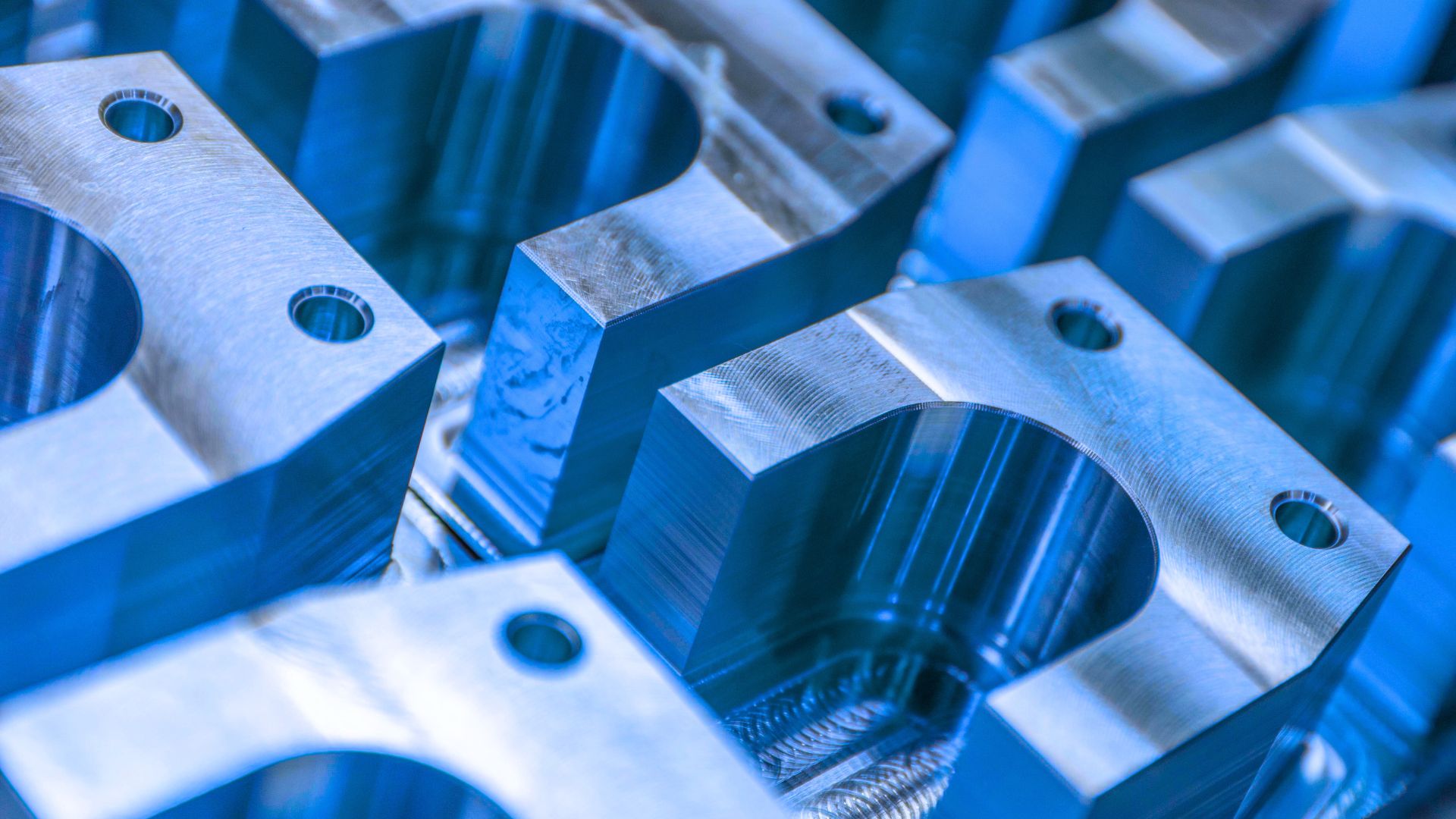

Conversion Coatings

Our state-of-the-art facility is designed to maximize batch quantities and production turnaround, ensuring the highest quality while maintaining competitive prices.

Anodizing

Kun-Scalexuss offers anodizing services, providing protective and decorative surface treatments for various industries, including aerospace, defence, and more.

Plating

We provide metal finishes that protect against corrosion, enhance electrical conductivity, and improve the appearance of components for major aerospace and other industries worldwide.

Passivation

Kun Scalexuss offers passivation services, providing protective and decorative metal surface treatments for major aerospace and other industries worldwide.

Painting

Kun Scalexuss offers a range of processes under one roof, featuring a spacious paint shop equipped to handle multiple paint applications.

Abrasive Blasting

Helps prevent corrosion and extend the lifespan of metal components. This process also ensures optimal adhesion, enhances durability, and improves the appearance of the final coating.

Testing Capabilities

Kun Scalexuss offers a wide range of testing capabilities for a variety of industries, in compliance with customer-specific and international standards.

Serving Since Three Decades

Sectors We Serve

Aerospace

Electroplating of aerospace components such as landing gears, engine parts, and fasteners to improve their wear resistance, corrosion resistance, and electrical conductivity.

Defence

Surface Treatment of defence components such as firearms, armored vehicle parts, and military fasteners to enhance their wear resistance, corrosion resistance, and electrical conductivity.

Medical

Electroplating of medical components such as surgical instruments, implants, and dental devices to improve their biocompatibility, wear resistance, and corrosion resistance.

We take great pride in our work and are committed to ensuring that every project receives the highest level of care and attention to detail.

Get Quick Help

Mr. Ashok P

+91 99455 12749