Conversion Coatings

Specialist In Conversion Coating

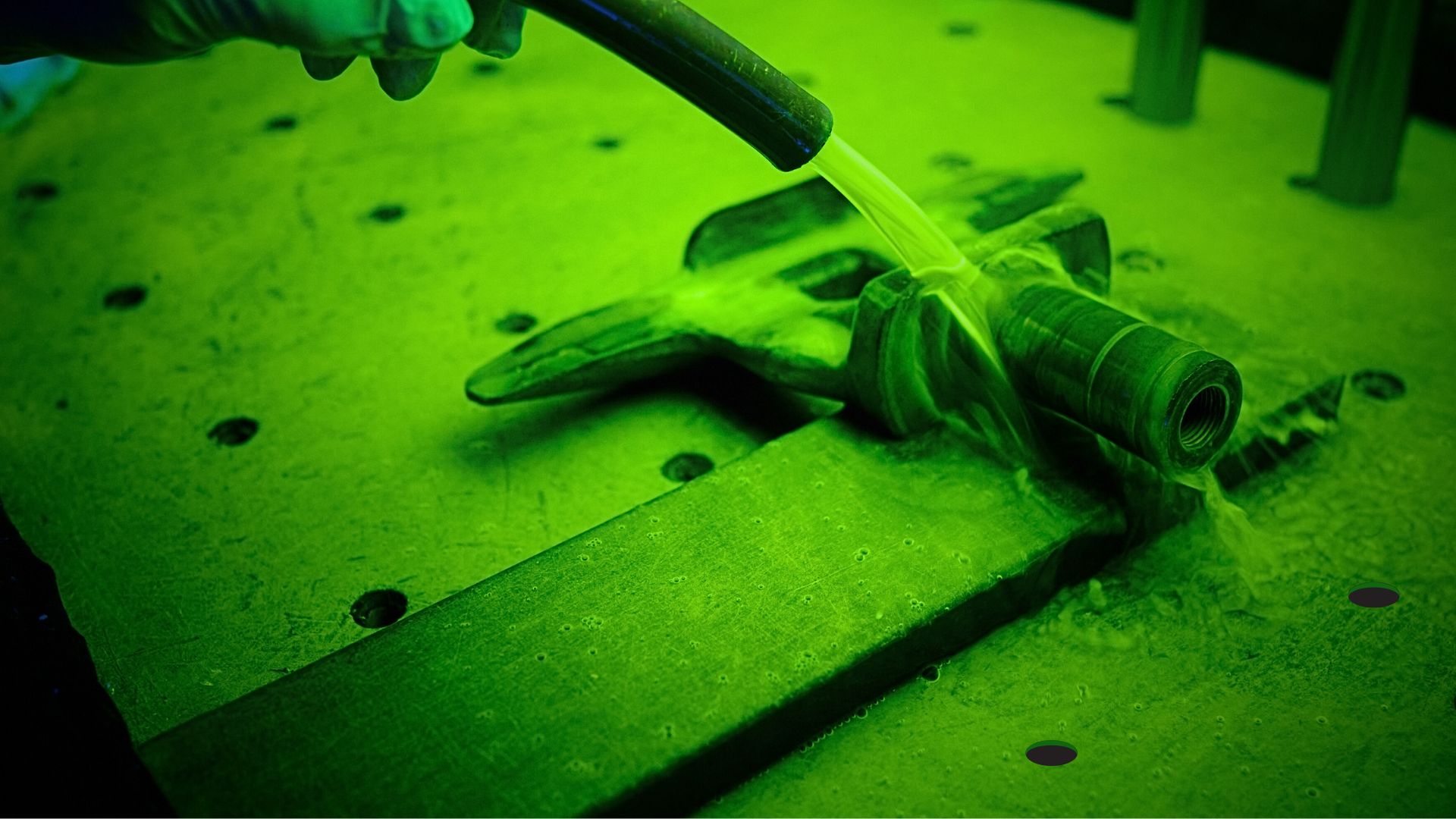

Conversion coatings provide corrosion protection, enhanced surface hardness, decorative color options, and serve as effective paint primers by transforming the part surface through chemical or electrochemical processes.

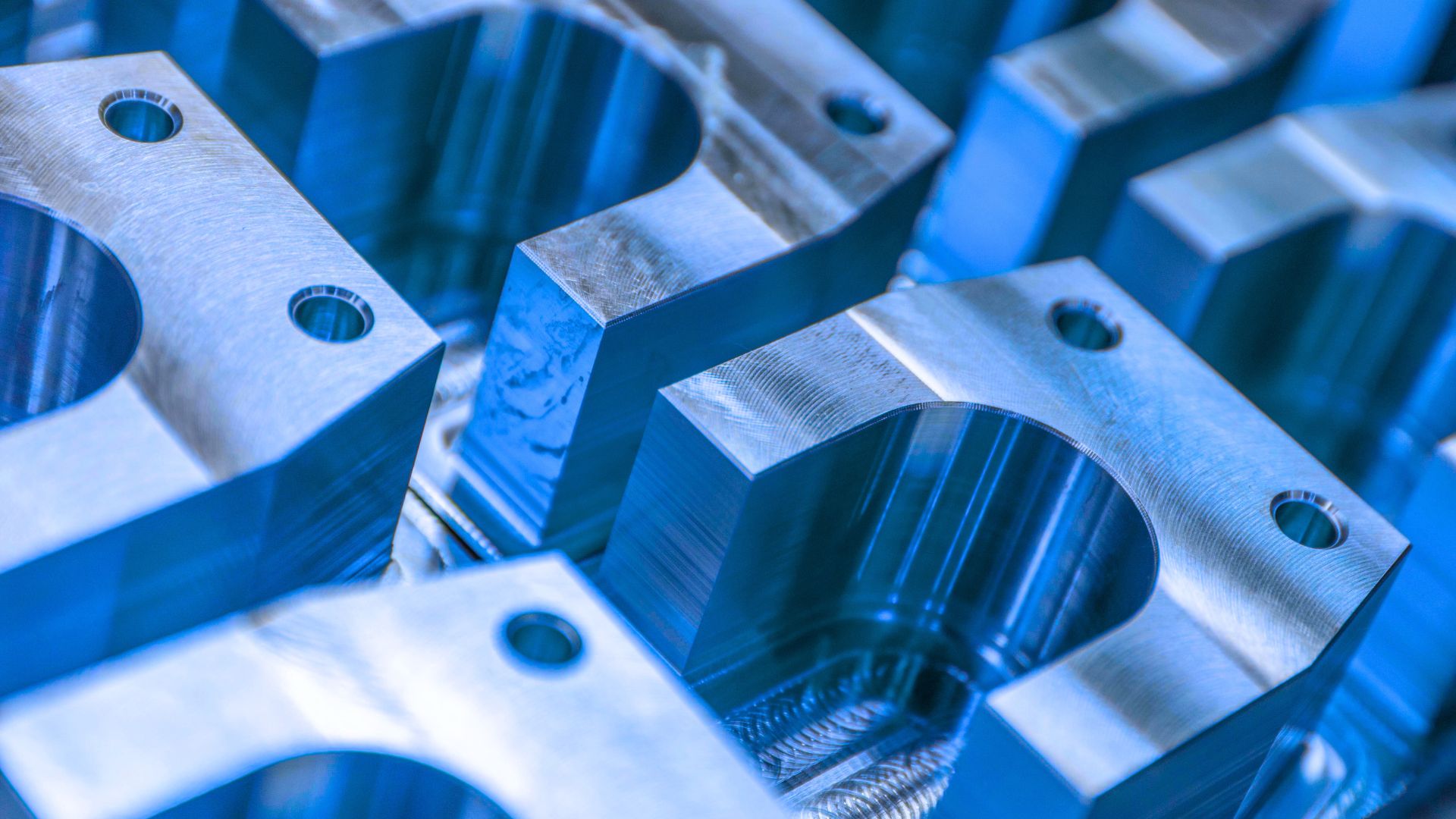

Kun-Scalexuss has built a strong reputation as a professional metal finishing company. Our comprehensive capabilities make us a one-stop shop for all your surface finishing needs, helping to reduce lead times and transit costs.

Who We Work With

We are trusted by companies across various manufacturing sectors, including aerospace, defence, and medical, to provide reliable metal finishing services

Chemical Conversion Coating |

Tank Dimensions (mm) |

| Alodine 1200S | 550 X 1200 X 800 |

| Surtec 650 | 550 X 1200 X 800 |

| Zinc Phospating | 600 X 600 X 600 |

Kun-Scalexuss has the capability to perform multiple conversion coatings using some of the finest process tanks in the country.

Our state-of-the-art facility is designed to maximize batch quantities and production turnaround, ensuring the highest quality while maintaining competitive pricing.

Conversion Coating Offered By Kun-Scalexuss

Alodine 1200S

Alodine 1200S is a hexavalent conversion coating commonly used in engineering to enhance corrosion protection for aluminium and aluminium alloys.

The application process can be performed by immersion or swabbing, resulting in a color range from light golden iridescence to brown, depending on the immersion time and the specific requirements of the finished component.

Surtec 650

Surtec 650 is a conversion coating that can be applied by immersion, brush, or the Surtec 650 pen method. It enhances the corrosion resistance of aluminium and aluminium alloys while providing protection against environmental factors.

As a trivalent, chrome-free alternative to Alodine 1200S, Surtec 650 offers an effective solution for those seeking more environmentally friendly options in metal finishing.

Zinc Phospating

The zinc phosphate conversion coating process transforms the metal surface into a polycrystalline coating containing iron, manganese, nickel, and zinc phosphates, providing an excellent base for paint adhesion. This process improves alkaline resistance and enhances adhesion and durability.

Applied via spray or immersion, it works on various substrates, including steel, galvanised steel, zinc-nickel alloys, and aluminium. After application, the zinc phosphate coating serves as a strong foundation for powder, electrocoat, or liquid paints, ensuring superior adhesion and corrosion resistance.

Specifications

For Aluminium

MIL-DTL-5541

ACES 16P5

PS114

For Steel

MIL DTL 16232

TT C 490

Certified with AS9100 Rev. D and NADCAP servicing 1st Tier Engineering and Prime companies.

Our Key Services

NDT and Etch Inspection

We make use of advanced technology and equipment to offer a non-destructive, accurate, and reliable method for assessing the quality of metals and alloys.

Conversion Coatings

Our state-of-the-art facility is designed to maximize batch quantities and production turnaround, ensuring the highest quality while maintaining competitive prices.

Anodizing

Kun-Scalexuss offers anodizing services, providing protective and decorative surface treatments for various industries, including aerospace, defence, and more.

Plating

We provide metal finishes that protect against corrosion, enhance electrical conductivity, and improve the appearance of components for major aerospace and other industries worldwide.

Passivation

Kun Scalexuss offers passivation services, providing protective and decorative metal surface treatments for major aerospace and other industries worldwide.

Painting

Kun Scalexuss offers a range of processes under one roof, featuring a spacious paint shop equipped to handle multiple paint applications.

Abrasive Blasting

Helps prevent corrosion and extend the lifespan of metal components. This process also ensures optimal adhesion, enhances durability, and improves the appearance of the final coating.

Testing Capabilities

Kun Scalexuss offers a wide range of testing capabilities for a variety of industries, in compliance with customer-specific and international standards.

Serving Since Three Decades

Sectors We Serve

Aerospace

Electroplating of aerospace components such as landing gears, engine parts, and fasteners to improve their wear resistance, corrosion resistance, and electrical conductivity.

Defence

Surface Treatment of defence components such as firearms, armored vehicle parts, and military fasteners to enhance their wear resistance, corrosion resistance, and electrical conductivity.

Medical

Electroplating of medical components such as surgical instruments, implants, and dental devices to improve their biocompatibility, wear resistance, and corrosion resistance.

We take great pride in our work and are committed to ensuring that every project receives the highest level of care and attention to detail.

Get Quick Help

Mr. Ashok P

+91 99455 12749