Non Destructive Testing & Etch Inspection

The Process

Non-Destructive Testing (NDT) is an inspection method used to detect flaws in materials without causing damage. It employs a range of techniques to evaluate the properties of a material, component, or system while preserving the original structure and chemical composition.

NDT is essential for effective asset maintenance. By not permanently altering the inspected component, it provides a valuable technique that saves both time and money in product testing, evaluation, troubleshooting, and research.

Kun-ScaleXuss takes pride in its experienced and meticulous NDT technician team, equipped with the expertise to select the best methods for detecting defects in your products.

Our inspection team utilizes a purpose-built, in-house metallurgical laboratory to perform various specialized processes in a dedicated area, using advanced optical equipment.

With our expertise in non-destructive testing (NDT) and etch inspection, we ensure the reliability and safety of your products, equipment, and plant assets. Our team understands the entire product cycle, from design and manufacturing to operations and maintenance.

Kun-Scalexuss utilizes advanced technology for non-destructive, accurate quality assessments of metals and alloys.

Our skilled team conducts critical etch inspections on finished parts for aircraft engines, using specialized optical tools in a dedicated inspection room.

Different Types Of NDT Services

Visual Inspection

Weld quality inspection is a commonly used laboratory testing method for Non-Destructive Testing (NDT). This process involves the visual examination of welds and is effective in detecting surface-breaking defects, as many welding flaws are located on the surface and can be easily identified through Welding Procedure and Welder Qualification Testing.

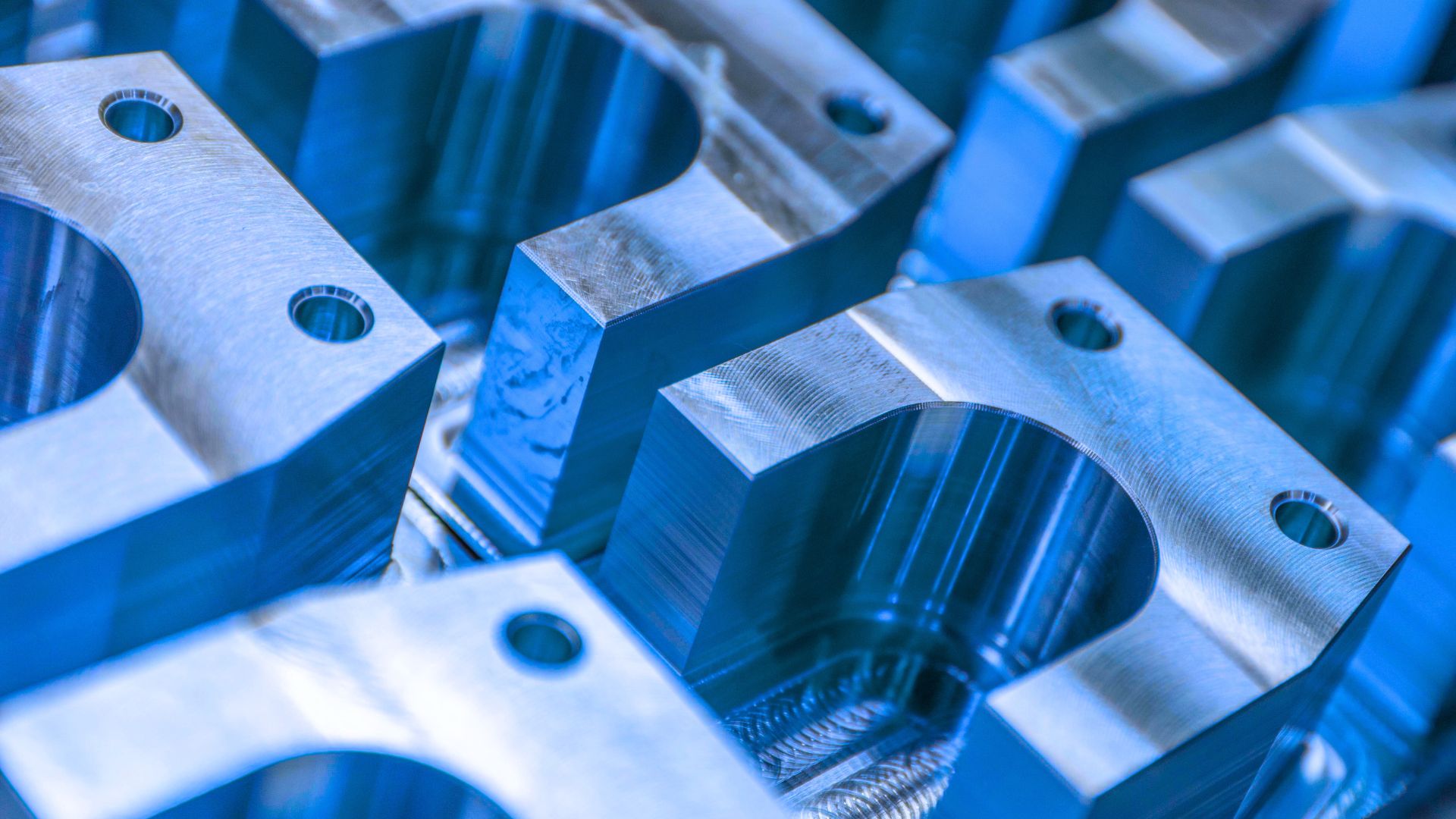

Etching of Hardened Steel Components

Inspecting hardened steel components is crucial to ensure they meet quality standards and prevent defects in the final product. This inspection involves sampling the steel and checking for any flaws.

A small piece of the steel is taken for examination, allowing for the identification of defects. If any issues are found, the steel can be corrected before final production, ensuring the integrity and performance of the end product.

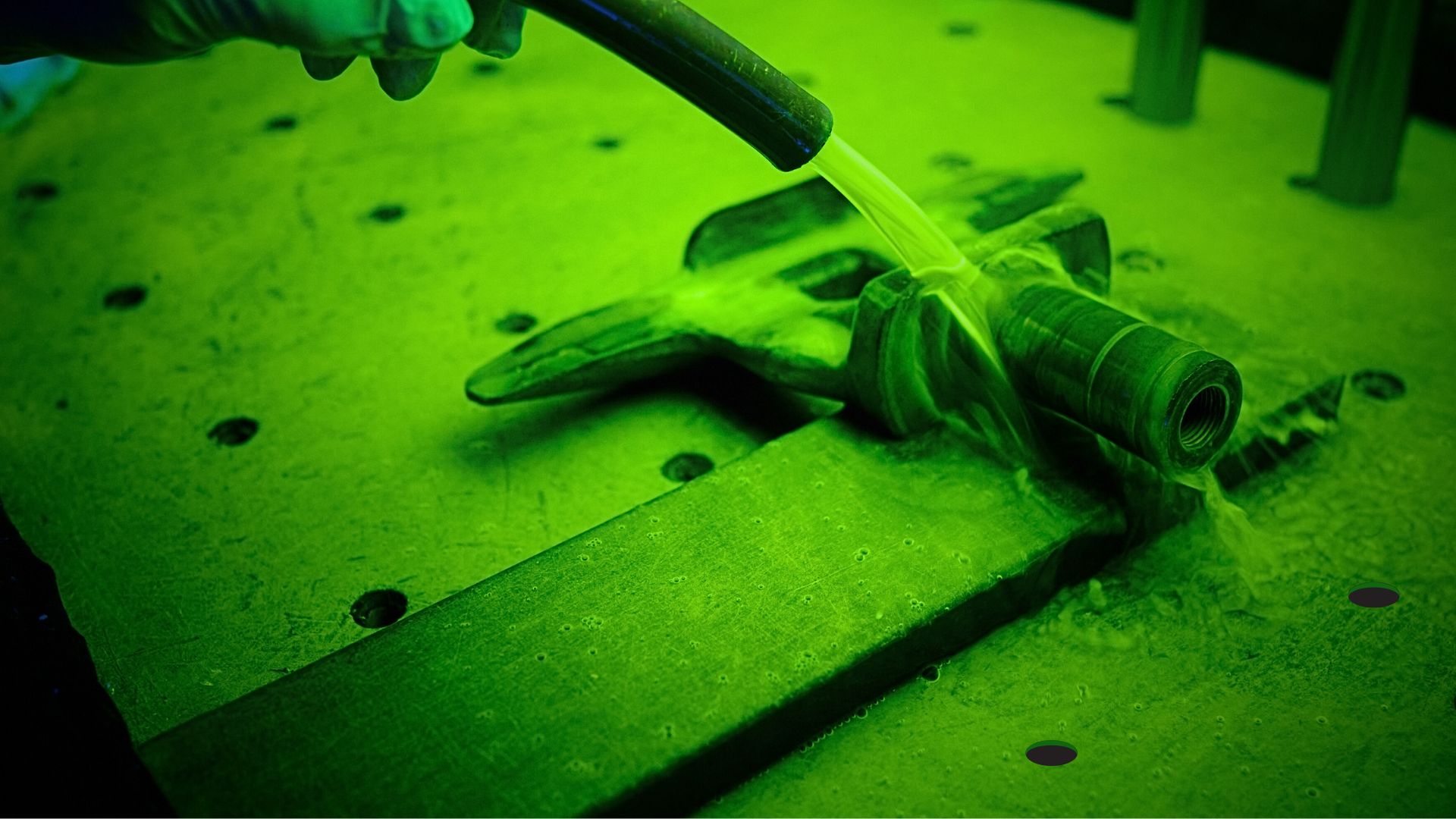

Non-Destructive Testing Fluorescent Penetrant Inspection

Fluorescent penetrant inspection is a fast and accurate non-destructive testing method used to evaluate the integrity of both ferrous and non-ferrous metals. This technique is effective for inspecting a wide variety of substrates.

Magnetic Particle Inspection

Magnetic particle inspection (MPI) is a quick and effective non-destructive testing method used across industries. It is applied to inspect components such as engine parts, suspension systems, castings, and welds.

MPI detects surface and near-surface defects (e.g., cracks, laps, seams, inclusions) in ferromagnetic materials like iron and steel. One of its main advantages is providing immediate feedback on the presence of defects or discontinuities.

Certified with AS9100 Rev. D and NADCAP servicing 1st Tier Engineering and Prime companies.

Our Key Services

NDT and Etch Inspection

We make use of advanced technology and equipment to offer a non-destructive, accurate, and reliable method for assessing the quality of metals and alloys.

Conversion Coatings

Our state-of-the-art facility is designed to maximize batch quantities and production turnaround, ensuring the highest quality while maintaining competitive prices.

Anodizing

Kun-Scalexuss offers anodizing services, providing protective and decorative surface treatments for various industries, including aerospace, defence, and more.

Plating

We provide metal finishes that protect against corrosion, enhance electrical conductivity, and improve the appearance of components for major aerospace and other industries worldwide.

Passivation

Kun Scalexuss offers passivation services, providing protective and decorative metal surface treatments for major aerospace and other industries worldwide.

Painting

Kun Scalexuss offers a range of processes under one roof, featuring a spacious paint shop equipped to handle multiple paint applications.

Abrasive Blasting

Helps prevent corrosion and extend the lifespan of metal components. This process also ensures optimal adhesion, enhances durability, and improves the appearance of the final coating.

Testing Capabilities

Kun Scalexuss offers a wide range of testing capabilities for a variety of industries, in compliance with customer-specific and international standards.

Serving Since Three Decades

Sectors We Serve

Aerospace

Electroplating of aerospace components such as landing gears, engine parts, and fasteners to improve their wear resistance, corrosion resistance, and electrical conductivity.

Defence

Surface Treatment of defence components such as firearms, armored vehicle parts, and military fasteners to enhance their wear resistance, corrosion resistance, and electrical conductivity.

Medical

Electroplating of medical components such as surgical instruments, implants, and dental devices to improve their biocompatibility, wear resistance, and corrosion resistance.

We take great pride in our work and are committed to ensuring that every project receives the highest level of care and attention to detail.

Get Quick Help

Mr. Ashok P

+91 99455 12749